Prostriedok proti páleniu

Prostriedok proti páleniu gumy

Prostriedky proti páleniu gumy sú základné prísady, ktoré zabraňujú predčasnej vulkanizácii (páleniu) počas spracovania a skladovania gumy, čím zabezpečujú bezpečnú manipuláciu a predlžujú trvanlivosť zmesi. Tým, že tieto činidlá odďaľujú predčasné zosieťovanie, zachovávajú tekutosť a spracovateľnosť materiálu, a to aj v podmienkach vysokých teplôt alebo pri zloženiach náchylných na spálenie.

Náš sortiment zahŕňaCTP(PVI)-80 aE-80, navrhnuté na bezproblémovú integráciu do rôznych vulkanizačných systémov. CTP(PVI)-80, vysoko účinný retardér, ponúka presnú kontrolu nad časom vytvrdzovania bez toho, aby boli ohrozené konečné vlastnosti vytvrdzovania. E-80 poskytuje vyvážené účinky oneskorenia, ideálne pre citlivé zmesi vyžadujúce prísnu bezpečnosť spracovania.

Tieto prostriedky umožňujú výrobcom optimalizovať efektivitu výroby, znižovať množstvo odpadu a prispôsobovať sa náročným technológiám spracovania, ako je vysokorýchlostné miešanie alebo systémy plnenia jemnými časticami, a zároveň minimalizovať nepriaznivé vplyvy na vlastnosti gumy. Naše prostriedky proti páleniu, ktoré sú nevyhnutné pri výrobe pneumatík, tesnení a priemyselného gumárenského tovaru, poskytujú spoľahlivú ochranu proti páleniu, čím zabezpečujú stálu kvalitu a prevádzkovú flexibilitu.

Použitie prostriedkov proti spáleniu do betónu

Prostriedky proti pripáleniu sú prísady používané predovšetkým v gumárenskom, plastikárskom a polymérnom priemysle na zabránenie alebo oddialenie predčasného vytvrdzovania (spálenia) materiálov počas spracovania. V kontexte súvisiacom s betónom je ich použitie menej bežné, ale stále relevantné v špecializovaných polymérom modifikovaných betónoch alebo náteroch.

V betónových alebo cementových systémoch sa môžu použiť prostriedky proti spáleniu, keď sa polyméry alebo gumové prísady zmiešajú s cementom na:

- Zabráňte predčasnému vytvrdnutiu alebo tuhnutiuspôsobené vysokými teplotami počas miešania alebo aplikácie.

- Skrátenie času spracovateľnosti, čo pracovníkom poskytuje dlhší čas na umiestnenie a dokončenie betónu alebo zmesí modifikovaných polymérmi.

- Zvýšte odolnosť a výkonzabezpečením správneho vytvrdzovania bez skorých chýb alebo slabých miest.

Napríklad v polymérom modifikovanom betóne (PMC), kde polyméry zlepšujú pružnosť a priľnavosť, pomáhajú prostriedky proti spáleniu kontrolovať reakčnú rýchlosť polyméru a zabraňujú predčasnému tvrdnutiu alebo spáleniu pod vplyvom tepla.

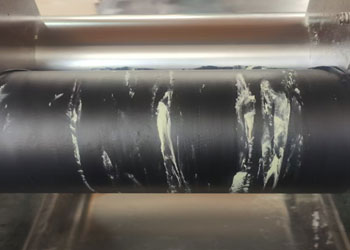

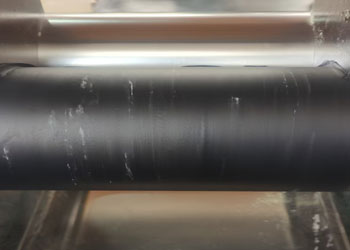

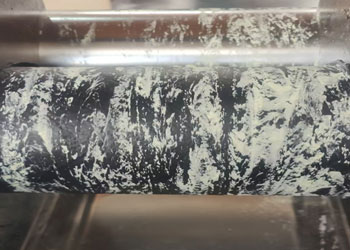

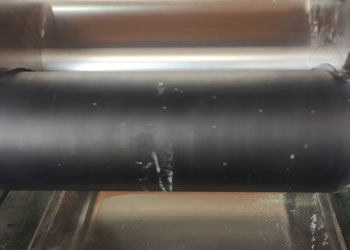

Porovnanie výkonu hnetenia valcov s práškovými výrobkami

| O 10 sekúnd neskôr | O 30 sekúnd neskôr | O 60 sekúnd neskôr | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.